The drive of demanding industrial equipment requires not only high power and torque. But also a robust construction, increased durability and also reliability. Find out what are the key features of low voltage electric motors, what should not be missing in their configuration and what to focus on during their regular maintenance.

Electric motors with very high outputs in the thousands of kW and exceptional power are often the only way to provide complex industrial drives. High voltage electric motors are quite a specific category. Adequate knowledge and experience are essential for selection, maintenance and also for the operation itself.

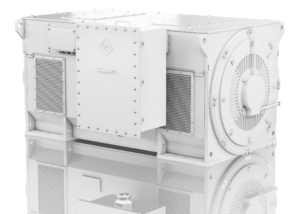

Key parameters of high voltage electric motors

High voltage electric motors IC01

Among the high voltage electric motors, you will generally find electric motors with an output from approximately 200 kW up to 30,000 kW, while it is not a problem to individually produce a more powerful electric motor. As the name implies, motors of this type are powered by high voltage. In practice you may encounter electric motors powered from 380 to 13,800 V. You can also choose the number of poles. Usually in the range from 2 to 12, depending on which you require a rotation speed from the electric motor.

Some aspects of maintenance of high voltage electric motors

Every electric motor requires some maintenance, this also applies to high-voltage electric motors, where regular maintenance is extremely important. It is necessary to regularly check the condition of the winding, insulating coatings, bearing wear, axial symmetry. Also perform tests of seals and joints. We definitely do not recommend neglecting the maintenance of HV electric motors in any way, as damages can have extremely negative financial consequences in this case.

What do I need to know when configuring a high voltage electric motor?